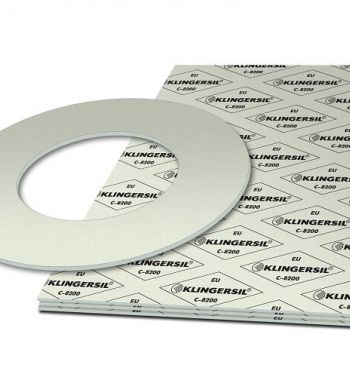

KLINGERSIL® C-8200

KLINGERSIL® C-8200 is a premium high-pressure gasket which offers more safety for the use with high concentrated acids.

Key features

Special acid-resistant elastomer as binder

Flame retardant binder

Benefits

Resistant to a variety of media especially acids

Improved ozone resistance

Typical technical data for thickness 2.0 mm

Compressibility ASTM F 36 J | % | 9 | |

Recovery ASTM F 36 J | % | 55 | |

KLINGER cold/hot compression | thickness decrease at 23 °C | % % | 7 15 |

Specific leakrate λ | VDI 2440 | mbar x l/s x m | 9.17E-09 |

Density | g/cm3 | 1.7 | |

Acid tests | |||

Thickness increase after fluid | HNO3, 96%, 18 h / 23 °C | % % % % % | unsuitable |

Average surface resistance | ρO | Ω | 5.8x10E11 |

Average specific volume resistance | ρD | Ω cm | 4.1x10E12 |

Average dielectric strength | Ed | kV/mm | 17.0 |

Average power factor | 50 Hz | tan δ | 0.228 |

Average dielectric coefficient | 50 Hz | εr | 9.4 |

ASME-Code sealing factors

for gasket thickness 1.0 mm | tightness class 0.1 mg / s x m | MPa | y 20 |

for gasket thickness 2.0 mm | tightness class 0.1 mg / s x m | MPa | y 20 |

for gasket thickness 3.0 mm | tightness class 0.1 mg / s x m | MPa | y 20 |

Function and durability

The performance and service life of KLINGER gaskets depend to a large extent on proper storage and fitting - factors beyond the manufactor’s control. We can, however, vouch for the excellent quality of our products. With this in mind, please also take note of our installation manual.